Modern microelectronics assembly requires clockmaker or robotic precission; sub-millimeter discrete components or pinout of integrated-circuits is nothing unusual. Building such highly integration devices from scratch at home is a virtually impossible, sometimes though fixing them with entry-level tools is still feasible.

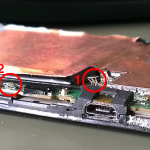

I was proud I could replace torn-off wires in my wash-mashine or fix corroded LED lighting inside dish-mashine. I did not suspect I could ever fix a smartphone even just 2 years ago when I was returning white HTC One X’s one by another due to failing yet crucial for me GPS antenna. Half year ago friend of mine shared a bad news that his white HTC One X fallen down and GPS was dead since then. As he did not bother anymore about crippled device, I decided to give it a try on my workbench. I was surprised how easy was to open unibody by lifting up display using plastic prying tools. Story about loose connection between board and antenna was true also this time: G-shock of smashed phone caused polycarbone body back to squeeze right-sided connectos that have lost tight touch – compare height of connectors (1) with non-corrected (2) on picture below. Using tweezers I bent slightly these springs and after assemblying back the phone GPS was brought back to life, tadaam!

Three months ago I bought Lenovo S650 to check if chineese really can make HTC One X (Endevoru) hardware by 2/3 cheaper. With slightly worse camera, no 3D acceleration (who cares) and not so sexy design they achieved same performance and even gained some more interesting features like dual SIM, external SD card up to 64GB and excellend front camera. First handset is performing perfectly to date. I got second S650 as a gift for teenage Julia just to face Murphy’s law. Device that came from different seller had scratched frame but barely noticeable. Worse issue was broken back camera – it did not focus at all, the micro-motor was failing every single time giving blurred pictures. That posed a problem, Lenovo does not offer support for its smartphones in Europe, so either I coud send back $120 worth smarphone for repair (paying $30 for shipment and wait another 2 months for handheld) or buy a new one (3 weeks to wait) and then repair and resell the other one… or FIX IT!

I made an optimal approach: I made an attempt to disassemble S650 without voiding warranty to see if camera is modular so I can replace it. I was delighted by the simplicity of construction as I needed just 6 phillips screws unscrewed and with a little help of prying tool plastic cover forming battery compartment just poped up. Using plastic SMT tweezer I disconnected modular camera from the from board and took a picture of it. All that within 5 minutes! Later on I searched thru GSM part stores on aliexpress.com and send quotation to 10 sellers. Two of them responded within one day. After a short email ping-pong I got best candidate: communicative and responsive seller with reasonable price of $20 for new camera module with free shipment. Deal done. Two weeks later I got tiny package in bubble foil with the same camera — another 5 minutes of work and voila! Camera works perfectly!

The story of fixed S650 did not end with camera. In long-term teenagers are deadly threat to smartphones: one month old S650 stopped charging, USB plug started moving loosely catching power only at specific angle. And again, 5 minutes disasembly, then another couple minutes to get access to USB compartment to discover cracked soldering – see below.

At this very moment the USB microscope came really handy. I could not even see a problem without serious magnification. I got Andonstar silver microscope following Dave’s positive opinion on EEVblog and I was not disappointed: really good for inspection and fairly usable for soldering at lower resolution (800×600 @30 FPS) I do assemblying WLS station components.

The lottery like quality of of S650 disqualifies it for majority of end-users. I have no doubt that chinese goods will suffer from such discrepancies as long as they will prefer dumping prices over extra QA. Another example is chinese USB 3.0 external HDD case I got with incomplete and imprecise soldering on SATA coonector that led to ocassional data corruptions until I reviewed and fixed it. For me it is kind of advantage as usually I can either fix it or ask for refund. And finally if bad times for IT come I can start reselling Lenovo smarpthones offering local service 😉