Problem is simple: 3.3V DC/DC converter has to work with high input voltage (>20V), has to be highly efficient as it works continuously in energy scarce conditions, and has to provide up to 300mA dealing with SD card bursts without noticeable voltage drops. While size is not a concern, it is not a smartphone, simplicity and cost (again) is a factor. Looking for optimum took me couple iterations.

Most of 3.3V stabilizers work with moderately low voltage. In my case output from solar charger gives from 11V (almost discharged battery at night) to nearly 22V (solar panel in full sun). Worst case is night when battery has to keep things working: voltage drop from 12V battery to 3.3V at 30mA of average output makes simple LDO a bad choice with efficiency at 25-30% level and more than 0.25 Watt is wasted as heat.

Charge pump.

I was considering non-inductive approach with charge-pumps at the beginning. Because it uses less components, or at least smaller, and has better efficiency than LDOs. Budgetary TLE4370 for half dollar a piece was put on workbench. IC works internally in two stages, first it uses charge pump to lower voltage to 8V and then uses precise LDO to give 3.3V. At this point I intuitively assumed that power loss lowers with increasing input voltage. To my surprise it turned to be false: at 60mA load on 3.3V side I measured nearly constant 60mA on input side even for voltage varying from 11 to 21 volts! And it was the same for 2nd and 3rd IC tested. Having same currents on input and output it meant I have equivalent of regular LDO in my hand without any benefits of double staged approach. TLE4370 landed in bag of components for future basic usages.Charge pump revisited.

Dozen of datasheets browsed I made my mind on LTC3245 with marketed efficiency of 81%. Reasonable prices of $8 and still good efficiency for my conditions (~70%) leads to two chips delivered to my workbench. Performance characteristics stands that input current is nearly constant when input voltage is varying: during tests with 60mA load on 3.3V I observed around 30mA of input current, value only halved comparing to LDO. But calculations show values close to efficiency charts – from 50% to 68%. Good enough for prototyping I designed this chip in PCB and continued other works.

Polymeric fuses.

Accidentally I verify short-circuit protection of LTC3245 with negative result: I got first chip burnt silently. Similar accidents with solar charger inspired me to use extra safety measures, including resettable fuse. While I used them in power-side of circuitry I could not use it on 3.3V DC/DC output. Multi-fuse is thermistor that reduces current when heated up and has non-zero resistance – it means it is too slow for fragile converted and 200mA/24V version with 2 ohms in cool conditions leads to significant voltage drops. I kept looking for more efficient and short-circuit resilient converter just to look back at inductive versions just to find LTC3630 also from Linear Technology.

Superefficient LTC3630

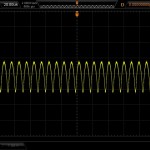

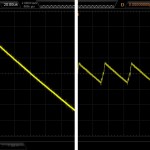

This tiny chip offers nearly 90% efficiency in 5-100mA range supporting up to 0.5A output current at a bit more expensive cost of $10-12. Prototype home made single-sided PCB was assembled 2 days after chip arrived from China. Power transformation through magnetic field worked way more effective – as expected, at constant output load I observed input current dropping with increasing input voltage. In tests measured efficiency was varying from 80 to 87% and shorting output I dare to test did not destroy the chip this time. Also playing with feedback RC bridge made output ripple voltage way stable than charge pump does: adding Ciset = 150pF to Riset = 100k reduced 280mVp-p ripple to 70mV under 10mA load, makes average output voltage closer to expected value (3.35V instead of 3.45V) at the price of a little drop in efficiency (from 83% to 79%). LTC3630 will replace LTC3245 in production.See also other related articles:

[posts_by_tag tag=”WLS”]